BioMesh Project

An

All-Hex

Meshing Strategy for Bifurcation Geometries

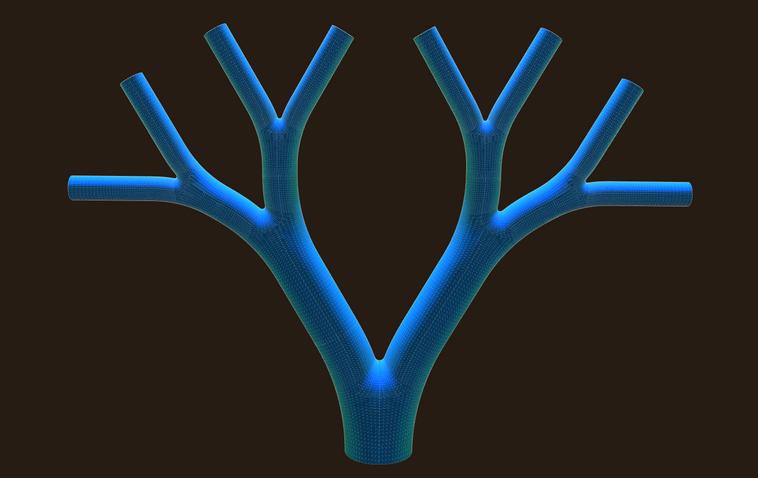

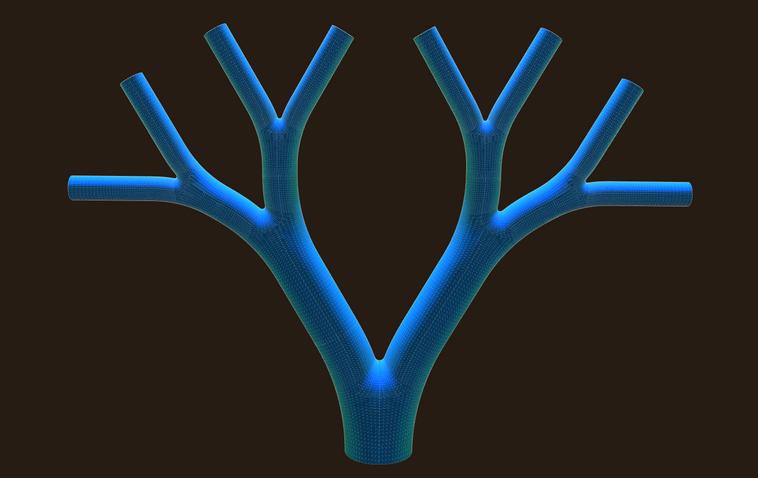

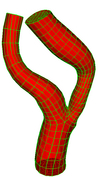

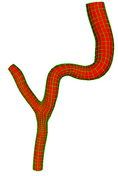

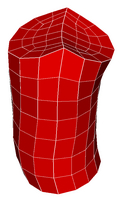

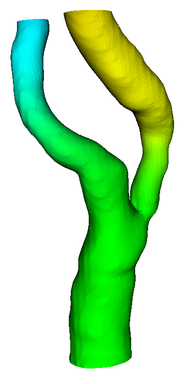

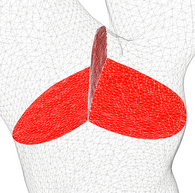

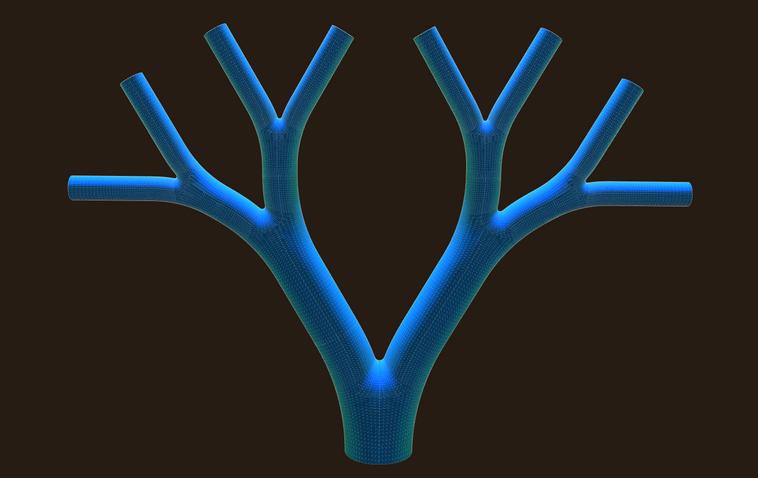

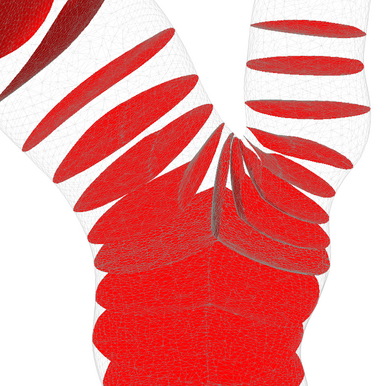

Single Bifurcation Model

|

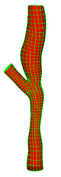

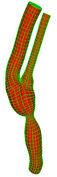

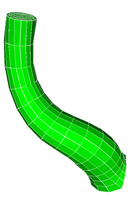

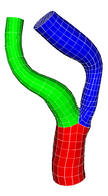

Multiple Bifurcation Model

|

|

|

Data Source:

Prof. Francis Loth, UIC

|

Data

Source : Arizona State University

|

Introduction:

Bifurcation

is very common in all

natural flow carriers (example

arteries,

veins etc.). Most of the numerical flow simulation using

Navier-Stokes

equations require a high quality discretization of computational domain

into 2D (Triangles, Quadrilaterals or Polygons) or 3D simplexes (

tetrahedra, hexahedral,

prism, or hybrid). The selection of element shape is decided by

the solver, accuracy and resource requirements. Unstructured

tetrahedral mesh, although,

much simpler to generate, may require large number of elements to

resolve very small scale

phenomenon compared to structured or

unstructured hexahedral mesh.

In this project, we implement a robust algorithm to generate All-Hex

elements in bifurcation and tubes arbitrary shapes arising in

subject specific computational hemodynamics modelling. The

key

components of our approach are the use of a natural co-ordinate system,

derived from the solutions of Laplace's equations

that follows the

tubular vessels. We demonstrate with many different geometric models,

that a very high quality hex mesh can be

generated in a fast and accurate way.

For the following geometric models, you may download

1. Surface Triangulation

2. Tetrahedral Volume Mesh

3. Hexahedral Volume Mesh ( Level I, II and III )

Acknowledge: All the visualization have been done using

ParaView Software.

Methodology:

Table of Contents

1. Introduction

2. Procedure

3. Performance

Results

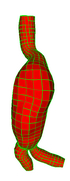

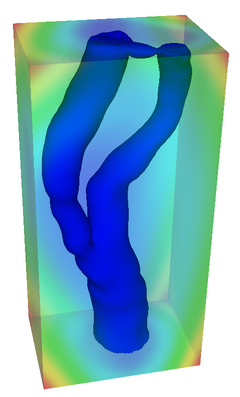

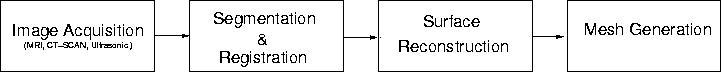

A general pipeline starting from image acquisition from various

modalities till the mesh generation for the numerical simulation is as

follows. One of the main goal of this project is to automate the

entire process with minimal human intervention.

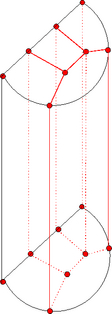

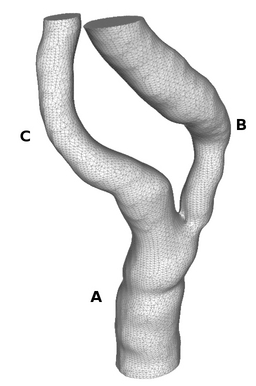

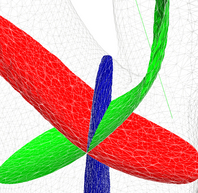

Given a general bifurcation geometry as shown below, our algorithm will

generate a high quality all hexahedral mesh in the tubular domain

satisfying two requirements:

- No two cross sections intersect.

- Each cross section is orthogonal to the vessel wall.

- Number of hexahedral elements must be small and predictable.

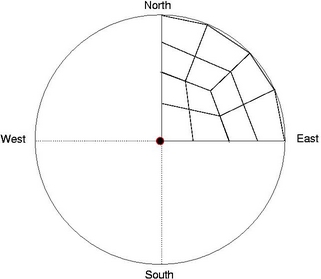

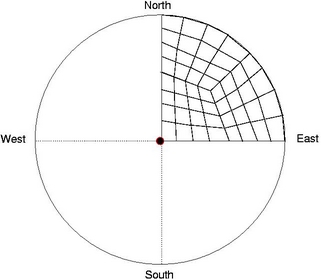

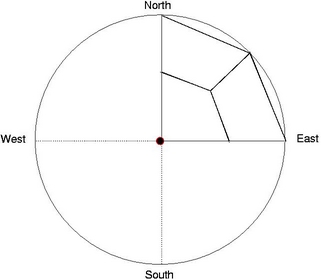

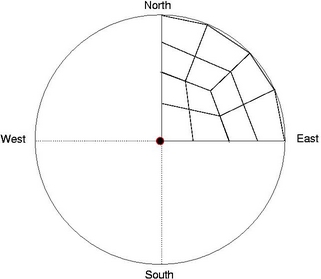

Fig: (I) Domain decomposition of a vascular geometry

into

six regions

(II) Each region is mapped to a canonical half cylinder

Some existing general purpose all-hex mesh algorithms

- Whisker Weaving ( Timorthy J. Tautges )

- Plastering ( Steven J. Owen )

- Medial Axis Decomposition

- Octree

All the above algorithms have been

used in varieties of applications.

Compared to a general purpose approach, our domain specific approach

has the following features.

1. Specifically designed for tubes and bifurcations,

2. Easy to

implement with reusable software

components ( > 90 % reuse)

3. Produce very high

quality mesh.

4. Number of mesh

elements and spacing can be controlled.

5. Numerically robust.

We have been using these geometries to study turbulence in human

carotid

arteries which develop atherosclerosis causing stokes. For more

details, read an article from Dr. Paul Fischer entitled "Stroke

Busters in Turbulent Blood"

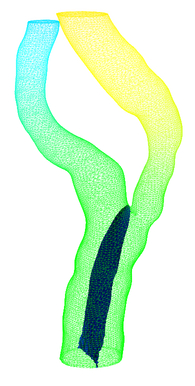

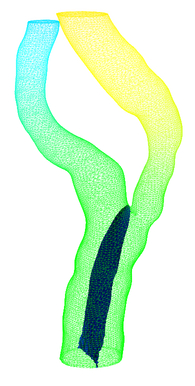

Domain Decomposition:

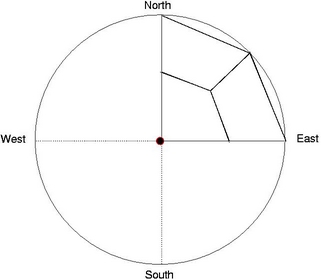

The fundamental problem with the bifurcation problem is related to

"Domain Decomposition". How can we divide the three vascular tubes into

three domain, each of the domain should be topologically equivalent to

a one-dimensional tube. The following pictures describe the

decomposition performed by our method.

Fig: Domain

Decomposition of vascular geometry into three tubes.

Basic Idea:

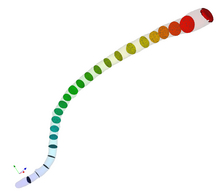

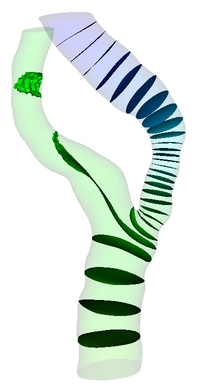

Consider an undulating tube with varying diameter. Let us solve the

Steady thermal conduction problem with the following boundary conditions

- T = Ta At the opening cap;

- T = Tb At the end cap

- On the side walls DT/DN = 0 where

N

is outward normal to the boundary surface.

Assume that Tb > Ta and now construct the isosurfaces

of

monotonically increasing sequence of temperatures Ta = a1 < a2 <

a3 .... =Tb. These isosurfaces will be non-intersecting and orthogonal

to the

wall. In other words, these isosurfaces create a natural

coordinate system.

Fig: Isosurface in an undulating

tube creates a natural coordinate system.

We want to extend this idea create all-hex volume mesh in bifurcation

geometries. In the following sections, we will explain the entire

process. For greater details, refer to our publication.

Short Description of the Procedure:

Step I: Surface Reconstruction

Let us assume that image segmentation and registration is already

performed and that produces a noisy point cloud. The first

step in the generation of the volume mesh is to produce a high quality

surface representation. Among the various schemes, Implicit Surface

Reconstruction using Radial Basis Functions ( RBF) and Surface

Reconstruction using Delaunay Triangulation (Dey, Ameta etc.) are the

most popular choices. For detail descriptions, refer to SRPC.

The following pictures shows surface reconstruction using RBF and

Delaunay Triangulation (DT). Perhaps the biggest advantage of RBF

is

in

filling gaps in an undersampled dataset. As shown in the

following picture II, RBF can also fill a gap in some unwanted regions.

This

necessitates visualization, manual clipping and therefore, hinders full

automation.

Input Point Cloud

|

RBF

Surface

|

Delaunay Surface

|

Fig: Surface

Reconstruction using Point Cloud

The following table shows that system of linear equations arising from

thin plate RBF are ill conditioned which become worse as the number of

sample points increases.

|

Matrix Size |

Condition

Number |

239x239

|

2.5645 x 10^5

|

447x447

|

1.1683 x 10^6

|

1256x1256

|

1.5976 x 10^7

|

Surface reconstruction using DT is extremely fast

and provably correct. Perhaps the only disadvantage of this

approach comes while handling undersampled dataset. However, it is

possible to

detect undersampling in the dataset while creating DT, therefore,

surface repair tools can be applied on the undersampled regions.

At a final step in surface reconstruction, mesh optimization

schemes 1) Edge Flipping 2) Non-shrinking surface

smoother (Taubin Smoothing, Mean Curvature flow, or Implicit Fairing

) are applied to remove additional noise in the dataset. For

details, refer to

SurfSmooth

Step

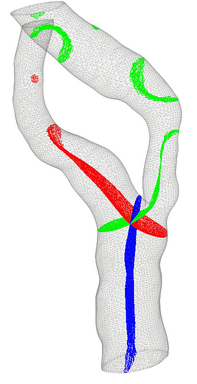

II: Classify Surface Vertices:

The output of step one is a

clean, noise free, smooth 2D

manifold surface triangulation. In order to solve the Laplace equations

(

described in the next section ), we have to

classify surface vertices into three categories i.e. surface (1) ,

inflow (2) , and

outflow (3 & 4) ( Assuming that in the following picture, the

inflow is at the bottom and two branches are

outflow). At least one vertex must be classified as

inflow and two vertices as outflow.

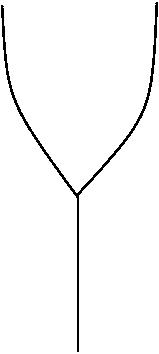

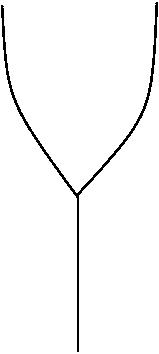

In order to automate identification of inflow and outflow vertices from

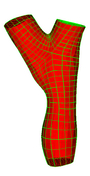

the surface model, a Reeb graph (or Medial Axis) is constructed which

has the shape of "Y". ( Reeb graphs is very simple to construct

compared to Medial Axis). The end point of the hand is "inflow" and the

fork ends are "outflow" vertices.

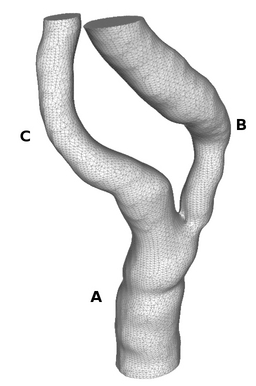

Surface Model

|

Reeb

Graph

|

Fig: (I) Surface Triangulation (II) Identifying end

points with approximate MD.

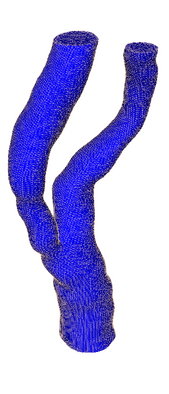

Step 3:

Tetrahedral Volume Mesh Generation

Using the surface triangulation as

constraint, generate a tetrahedral

volume mesh. (Many Delaunay triangulation based software may insert new

vertices on the surface). Since the

quality of the volume mesh

is not critical for the final hex mesh generation, therefore, any

suitable

tetrahedral mesh generation ( of course without slivers ) can be

used.

In our case, we used SolidMesh software based on

Advancing

Front Technique (AFT) to

obtain the

tetrahedral volume mesh.

If the surface is not properly sampled or has holes, we use RBF

Implicit surface reconstruction algorithm to create a smooth 2D

manifold surface. In this

procedure, too many triangles are generated

that are needed to solve the heat conduction problems and subsequently

mesh generation. Therefore, a

coarser grid is obtained by finding "Independent Set" from the

mesh graph. "Topological Noise" is the biggest problem in the

surface reconstruction through implicit polygonization. The

holes can be identified by calculating Euler Characteristic of the

surface. At present, we don't have robust implementation to

remove the "Topological Noise", therefore, we experimented with

different spacing in MC and were able to get zero genus surfaces.

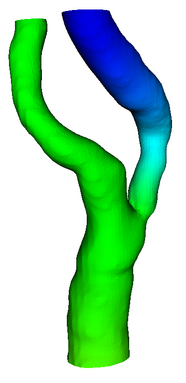

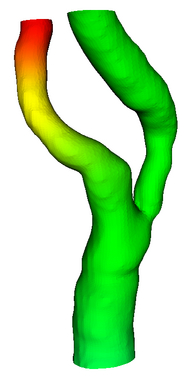

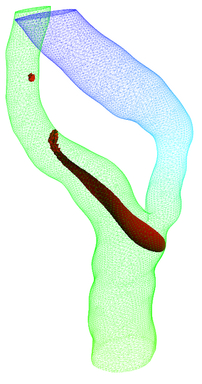

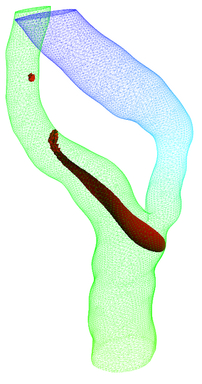

Step 4: Solving

Heat Conduction Problems:

As described in the paper the central

theme of our approach is to

create

a natural co-ordinate systems by solving three different Laplace

Equations with the following Dirichlet and Neumann

Boundary Conditions. For this purpose, standard Finite Element

Formulation ( FEM) is used. The symmetric, positive definite

system of linear equations arising from FEM is solved using

Preconditioned Conjugate Gradient method. ( We used Matrix Template

Library MTL for Matrix objects and Iterative Template Library ITL for

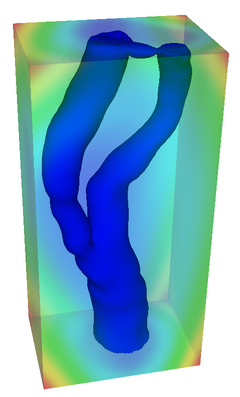

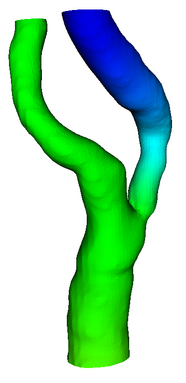

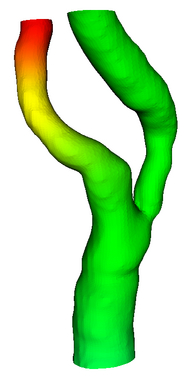

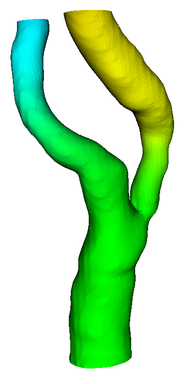

PCG) . The color plots of the temperature

distribution are shown in the following pictures.

Branch

A: Insulated

Branch B: -Ta

Branch C: 1-Ta

|

Branch

A: 1-Tb

Branch

B: Insulated

Branch

C: -Tb

|

Branch

A: -Tc

Branch

B: 1-Tc

Branch

C: Insulated

|

Fig: Temperature distribution

Observe that there is rotational symmetry in the boundary conditions,

which can be exploited to reduce the code size. How should we select

the Dirichlet Boundary condition values ? We can choose any

two values, but any arbitary values may not give a same value on

the insulated cap for all the three cases ( It is must and the reason

will be explained later). Therefore, for each case, we solve

Laplace solver twice in order to ensure that the end cap of each

insulated boundary is maintained at the same value.

For each case, in the first run, we specify Dirichlet values 0

and 1 at two ends. This will create some temperature ( let us say

alpha) at the cap of insulated boundary. In the second run,

Dirichlet Values are shifted by alpha, so that the temperature at

the center of the insulated end cap becomes zero.

The Isosurface emanating from the center of insulated caps are called

"Principal Isosurfaces".

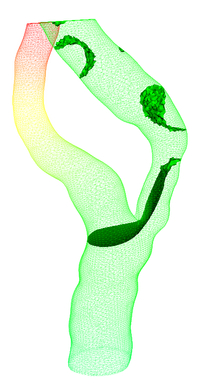

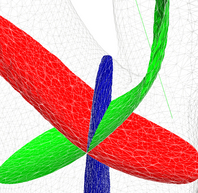

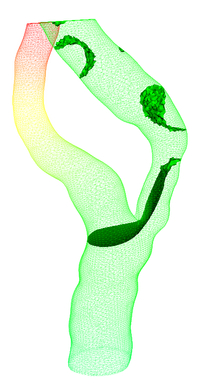

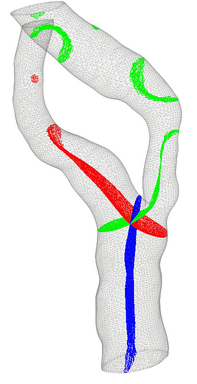

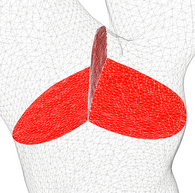

Step 5:

Constructing Primary Chips:

Obtain the three iso-surfaces at T =

0 from each solution. Ideally,

with the exact arithmetic, we should get a smooth surface from the

centre of insulated cap and right upto the end near the

bifurcation, but as

shown in

the pictures, iso-surface away from the centre are jig jagged and

sometimes there may be pockets of

isolation. This behaviour is because of finite numerical

precision, but our region of importance (ROI) is

the "Bifurcation Centre", where all three iso-surface are smooth.

Fig:

Isosurfaces from the solution of heat conduction problems.

IsoSurface A

|

IsoSurface B

|

IsoSurface C

|

Intersection of IsoSurfaces

|

Fig: Creating principal chips with principal isosurfaces which emanates

from the insulated BC branch.

Use implicit surface cutter to remove the part of the surface that is

not required.

Zoomed Picture

|

Primary Chips

|

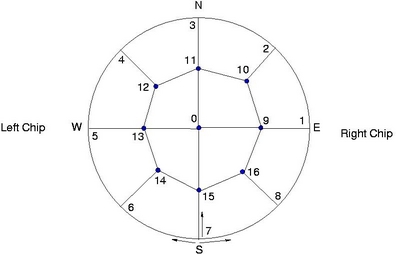

Topology of A Chip

|

|

Fig: (I) A zoomed picture of Principal Chips ( A and B).

(II) Topology of each chip. (III) A half cylinder

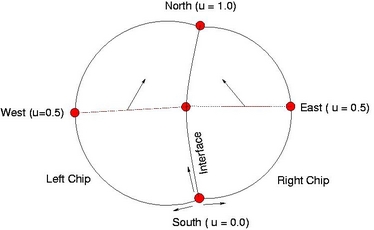

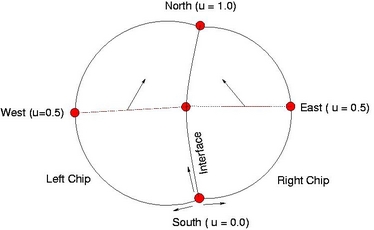

"South Vertex" of the primary

chip acts as a reference point for

the

proper orientation of the subsequent chips. Three curves (left, right,

and Interface boundary) are parameterized with

south (u = 0.0) and north (u= 1.0). East, West and Center vertices are

then determined at u = 0.5 along these curves.

Step 6:

Constructing Split and Simple Chips:

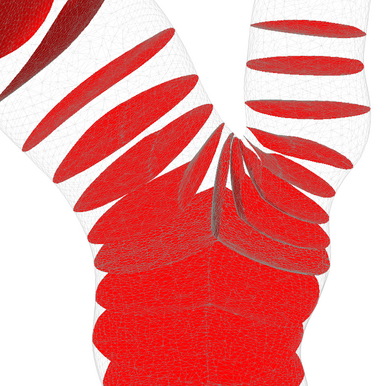

As we move away from the bifurcation

region, the angle between the left

and right chip decreases ( as shown in the zoomed picture below) . When

the angle between right and left chip

become less than 10 degrees, ordinary chips

are constructed from the isosurface in the branch.

Chips in Artery

|

Zoomed Region Near the Bifurcation

|

Note: Simple chips near the end caps may be distorted or cut

depending upon the geometry and boundary conditions applied on selected

vertices. There are two options (1)

Reject the chips that are not proper (2) Start with an

artificially extended branch and then discard all the chips in the

extended branch.

Pseudo-codes for constructing Split and Simple chips are given below.

Note that Isosurface extraction and implicit surface cutter are the

only two software modules that are required to create chips. Also note

that, isosurface extraction from tetrahedra mesh will be called large

number of times and it is the most expensive compared to other calls,

therefore, any optimization can have significant improvement in the

efficiency of the algorithm.

Algorithm: ConstructSplitChip ( tetmesh, branchID,

isoVal,

center0)

//********************************************************************************

// Input Parameters:

// branchID : The branch in which which Split chips

are created.

// IsoVal : Temperature

value for which the right surface of the chip is constructed.

//

The left side depends on the location of the right ( because of

alignment).

// center0 : Approximate

center of the previously generated chip.

//*********************************************************************************

bA = ( branchID+0)%3

bB = ( branchID+1)%3

bC = ( branchID+2)%3

// Search for right half of the chip separated by distance "width"

while(1) {

rightmesh = getSurface( tetmesh, isoval, bA)

cutmesh = getCutSurface( rightmesh, 0.0, bC) //

Implicit Cut the surface

interface =

getInterface(cutmesh)

// Extract the Cut boundary contour

center1 = getCenter(

cutmesh)

// Get the center of interface contour

if( dist( center0, center1) > width) break;

}

discard( rightmesh,

-1)

// Remove the left portion of the righmesh.

addInterface( chip,

interface)

// Add the interface

addSurface( chip, rightmesh,

1) //

Remaining mesh constitutes right half of the chip.

// Create left half of the chip, such that interface align together.

isovalB = getIsoValue( center1,

bB)

leftmesh = getSurface( tetmesh, isoValB, bB)

cutmesh = getCutSurface( leftmesh, 0.0, bC)

discard( leftmesh,

1)

// Remove the right side of the leftmesh.

addSurface( chip, leftmesh,

-1) // Remaining

mesh constitutes left half of the chip.

Algorithm : ConstructSimpleChip(

tetmesh, branchID, isoVal, center0)

trimesh = getSurface( tetmesh, isoVal, branchID)

addSurface( chip, trimesh)

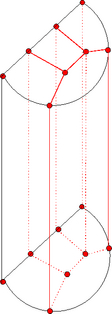

Step 7:

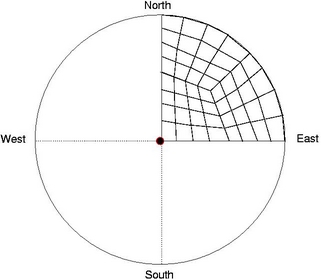

Apply Mesh Templates on each Chip:

Each Chip can be divided into four

quadrants and user defined mesh

templates as shown below can be applied on each chip. Vertices are

always projected on the chip surface

constructed by the isosurface. With increasing level of subdivisions,

better approximation of the outer surface is obtained.

Level-0 Mesh Template

|

Level-I Mesh Template

|

Level-II Mesh Template

|

Fig: Examples of Mesh Templates.

Step 8:

Smoothing QuadMesh on each Chip:

Isosurface generate

triangulated surface which acts as a

background mesh on which the quadrilateral mesh is superimposed. The

quality of quadrilateral mesh depends on the

node distribution on the background mesh. As the number of levels

increases, two or more points

may project on the same node of the background mesh which will result

in zero edge length of some

quadrilaterals. Therefore, it is essential to apply smoothing,

after mesh template is

applied. Experiments shows

that, 4-5 steps of Taubin's smoothingis sufficient to get very good

quadrilateral mesh.

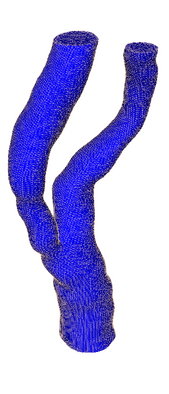

Step 9: Create

Volume Mesh:

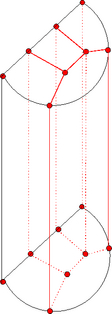

After consistently orienting each

chip with respect to the

primary chip, volume mesh is constructed using quad-mesh from two

consecutive chips. As the number of chips and

quad-mesh is deterministic, total number of hex-elements is also known.

In order to ensure that each hex is positive, Jacobian at each eight

nodes is checked.

Step

10: Apply Volume Mesh Optimization and Obtain Quality

Statistics.

The quality of the volume mesh may be

further improved by using

standalone Mesh Optimization Tools ( such as Mesquite). Volume

mesh, however, can not be improved beyond a limit unless the

surface mesh is also improved and/or topological flipping operations

are carried

out. (At present, we have not implemented these optimization)

Out of many quality measures, we measure only few to ensure that the

correctness of the final volume mesh.

1. MinMax Volume.

2. MinMax Aspect Ratio

3. Worst Condition Number.

Performance Results:

Module

|

Time ( in

seconds)

|

Vertex

Classification

|

|

Heat

Conduction Problems

|

|

Chips

Construction

1. Primary Chips

2. Split Chips

3. Simple Chips

|

|

Mesh

Templates

1. Level I

2. Level II

3. Level III

|

|

Mesh

Smoothing

|

|

Volume

Meshing

|

|

Volume Mesh

Optimization

|

|

Quality

Checks

|

|

Software:

Presently, the source code is not

ready for public distribution.

Please contact Dr. Paul Fischer (E-mail: paul@mcs.anl.gov)

for further information.

File Format:

All the files are in ASCII and the data format is as follows. For order

of connection, refer to MeshDatabase

#Nodes Number of Nodes

x1 y1 z1

x2 y2 z1

.

.

.

xn yn zn

#Triangles Number of Triangle

v11 v12 v13

v21 v22 v23

.

.

.

vn1 vn2 vn3

#Quads Number of Quads

v11 v12 v13 v14

v21 v22 v23 v24

.

.

.

vn1 vn2 vn3 vn4

#Hex Number of Hex

v11 ... v18

v21 ... v28

.

.

.

vn1

...

vn8

Note: All vertex index starts from 0 ( not 1 as in FORTRAN) and

are contiguous.

Presentation:

14th IMR Conference, San Diego Presentation 13th Sep, 2005 Download Presentation.

(The paper is also available

in the Proceedings of the 14th International Meshing

Roundtable )

Publications:

- An All-Hex Meshing Strategy for Bifurcation Geometries in

Vascular Flow Simulation

Chaman Singh Verma, Paul F.

Fischer, Seung E. Lee, F. Loth

14th

International Meshing Roundtable Conference-11-14 Sep, 2005, San-Deigo,

California

Download

Paper

- Re-engineering Legacy Code with Design Patterns: A Case Study in

Mesh Generation Software

Contact :

Paul Fischer

Mathematics and Computer Science Division

Argonne National Lab

fischer@mcs.anl.gov

|

Francis Loth

UIC College of Engineering,

FLoth@uic.edu

|

Chaman Singh

Verma

Mathematics and Computer Science Division

Argonne National Lab.

csverma@mcs.anl.gov

|

|

Last Modified: Wed Sep 31

17:03:06 CDT 2006