In February of 2024 this embedded PC/microcontroller was involved in an incident and very likely had -48V applied on the CAN-bus cables. In a (succesful) attempt to recover system logs, the controller booted OK but neither CAN-bus worked. Due to the nature of the event, the system is beyond repair; it is scrap. As such, I can't resist investigating the nature of the CAN-bus failure.

The CAN data bus uses two wires (CANH/CANL for high and low) between all devices, 120 ohm nominal bus impedance. This particular controller additionally supplies +5 and ground on the same 6-wire bus cable. The controller reported CAN bus receive and transmit errors, even with good termination.

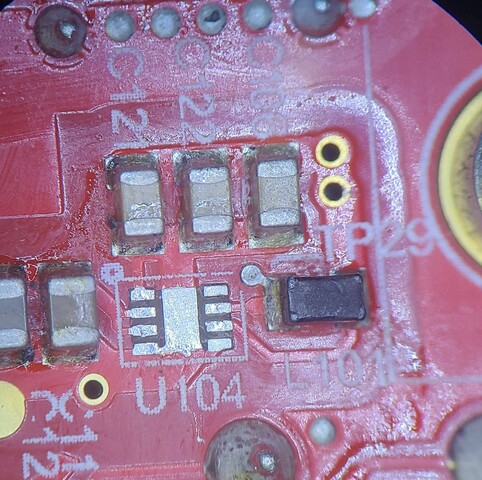

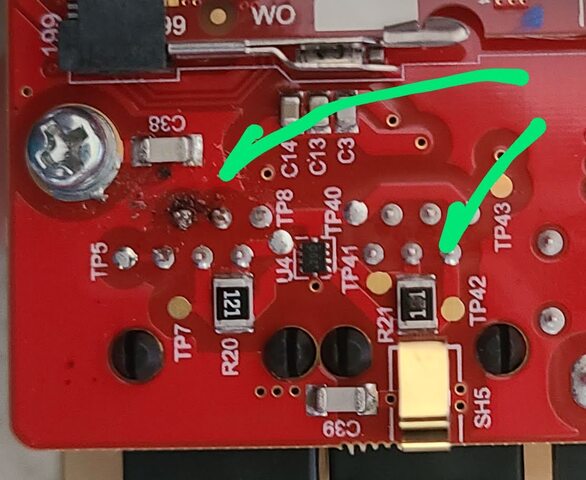

Upon disassembly, weird residue (something got hot?) on the MMJ jack terminals and R21, a

0.5W 120 ohm CAN termination resistor damaged. U4 is a 10UQFN TVS diode. I replaced it.

Closeup of R21, one of the bus termination resistors.

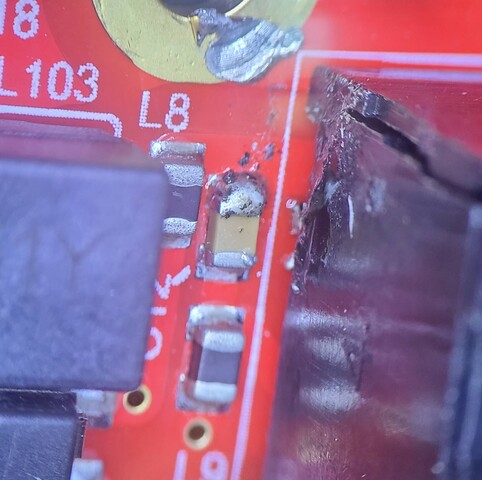

In circuit prior to the CAN transceivers is a series ferrite bead, L7.

One of the MMJ CAN jacks -- blown out on the back.

Wider view of the board - the ISO1050 CAN transceivers, according to the datasheet

provide some protection from -27V to 40V, etc. etc. With consideration to time

and the $3 single-quanity price, I replaced these as well.

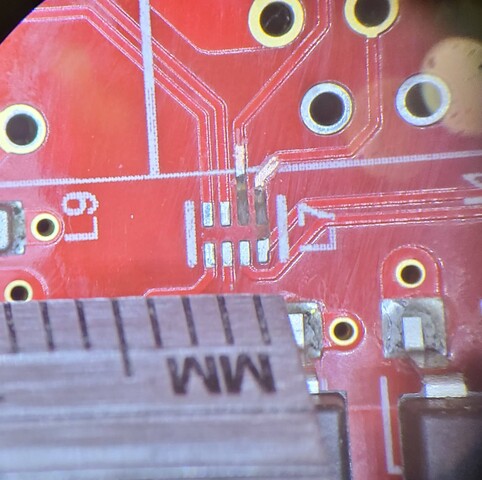

L7 / series inductor removed, pads cleaned. Steel rule for scale. Some board traces

were destroyed.

Device replaced, traces replaced as best as possible. Could be better, could be worse.

In any case, it works.

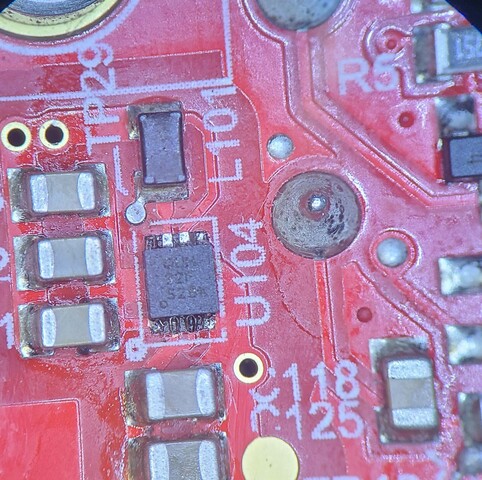

At this point all visually-damaged components were replaced. The CAN bus was still inoperable. Checking voltages on the board, the ISO1050 transceivers were receiving +3.3V on the input (within specifications) but only +2.7V on the output. That should be +5V. Without schematic the location of the regulator was not obvious. A day or two passed and I revisited with my IR camera. Glowing brightly on the board was U104, a TPS62173 5V, 500mA buck regulator -- reaching near 150F within a few moments of power-up. With the very small size and thermal mass, the hot component was almost impossible to discover without an IR camera.

Part masked off with foil prior to hot air removal. The device back serves as a

heatsink and takes a fair amount of both preheat and heat to remove. I find that

a foil mask effectively masks adjacent components from the heat, at least to the

degree that their solder doesn't reflow.

Replaced. Reflow could be more even but "good enough".

After replacing the regulator, the CAN bus returned to working as expected.

Due to the event and nature of my ham-handed repair I'm just going to leave this controller at my desk for a 'test' unit -- evaluating new firmware, etc. -- and labeled to never be placed in production service.

This page last modified Thu Mar 13 22:37:56 CDT 2024 by timc!